Timing Belt coatings

Overview of the coating possibilitiesIn order to protect the timing belts against external influences or to achieve better grip, ATLATOS® PU Timing Belts can be coated with various different materials.

ATLATOS® PU Timing Belts of the productlines Linear, Flex and Drive can be coated with various materials to make our products able to fulfil an enormous number of different applications. The selection of the right coating is based on your wishes and the applications requirements.

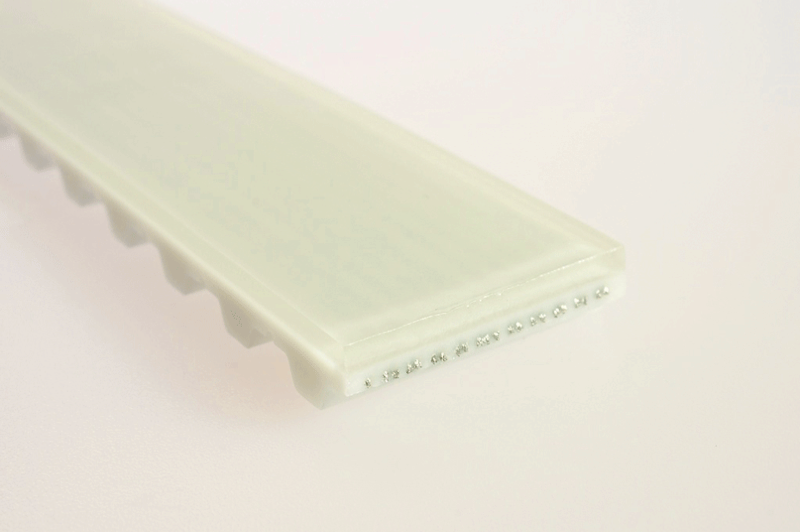

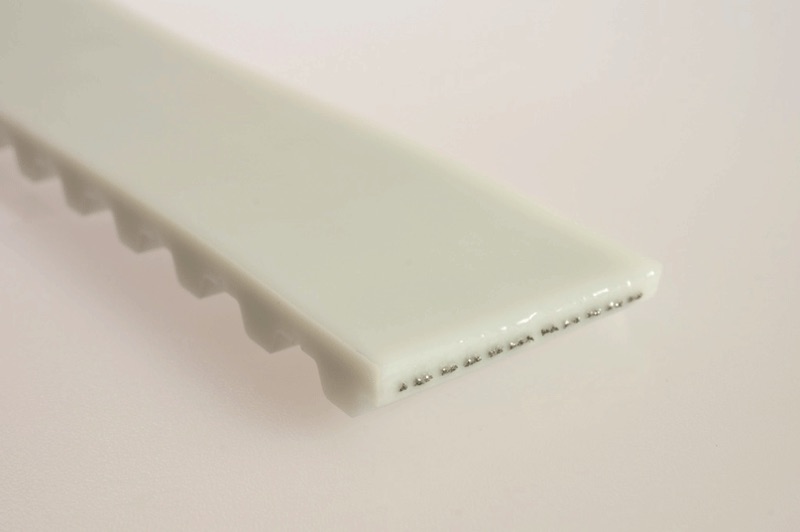

TPU 85 transparent

| Thickness | 1 / 2 / 3 / 4 / 5 / 6 mm |

|

Material / Hardness |

Polyurethan / 85° Shore A |

|

Colour |

transparent |

|

Surface |

smooth |

|

Temperature range |

-30°C / +80°C |

|

Food approval [FDA] |

No |

|

Pulley Factor |

30 |

Product features: good chemical-, oil- and fat-resistance

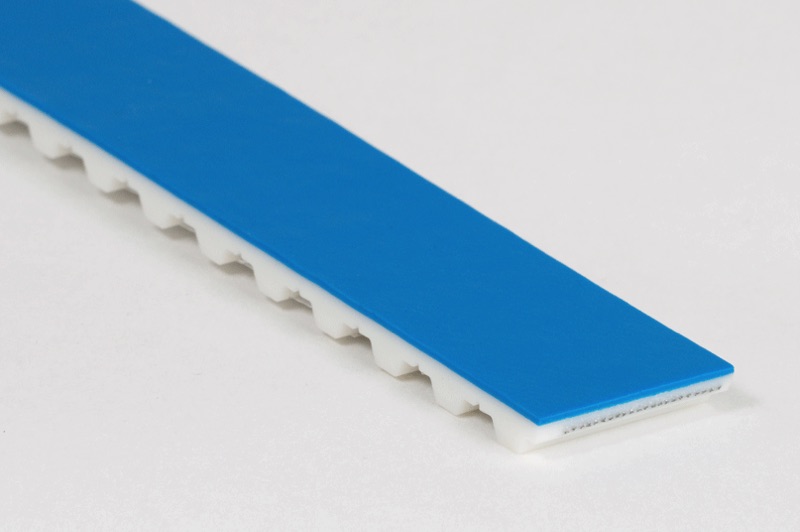

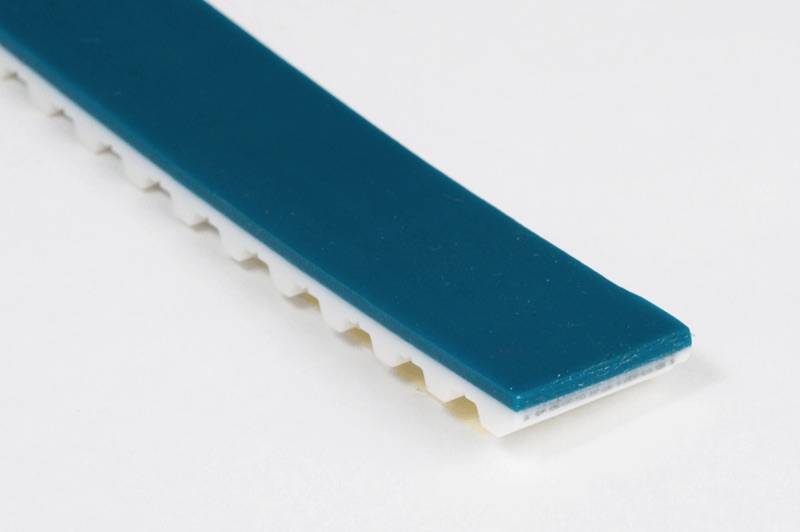

TPU 85 sky-blue F

| Thickness | 2 / 3 mm |

|

Material / Hardness |

Polyurethan / 85° Shore A |

|

Colour |

sky-blue |

|

Surface |

smooth |

|

Temperature range |

-30°C / +80°C |

|

Food approval [FDA] |

yes |

|

Pulley Factor |

30 |

Product features: high oil- and fat-resistance

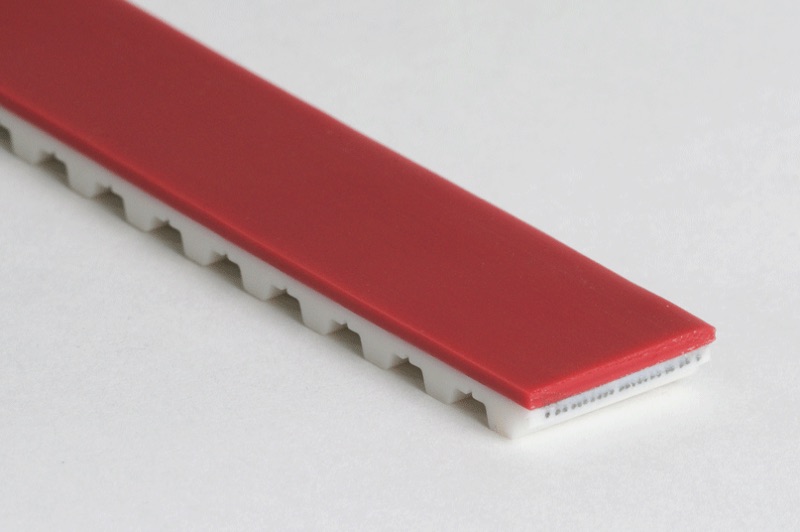

TPU 60 red

|

Thickness |

2 mm |

|

Material / Hardness |

Polyurethan / 60° Shore A |

|

Colour |

red |

|

Temperature range |

-30°C / +80°C |

|

Food approval [FDA] |

no |

|

Pulley Factor |

25 |

Product features: abrasion, oil- and fat-resistance

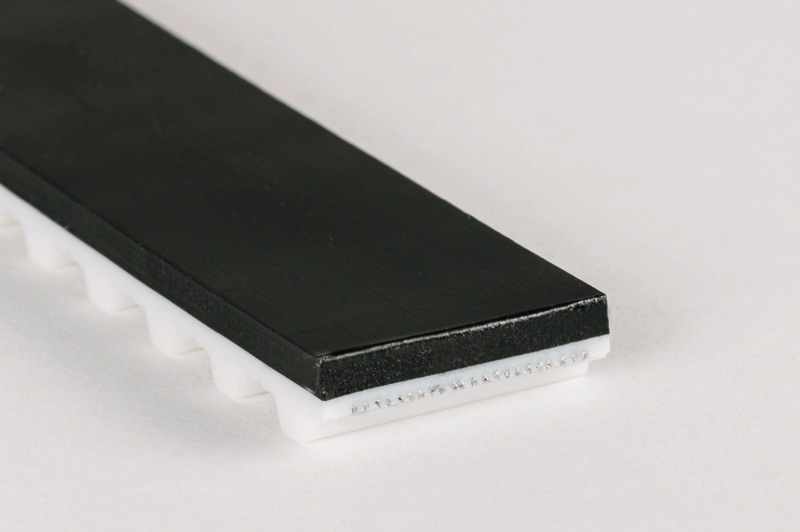

TPU 60 black

|

Thickness |

2 / 3 mm |

|

Material / Hardness |

Polyurethan / 60° Shore A |

|

Colour |

black |

|

Surface |

smooth |

|

Temperature range |

-30°C / +80°C |

|

Food approval [FDA] |

no |

|

Pulley Factor |

25 |

Product features: abrasion, oil- and fat-resistance

TPU 70 transparent

|

Thickness |

2 / 3 mm |

|

Material / Hardness |

Polyurethan / 85° Shore A |

|

Colour |

white |

|

Surface |

smooth |

|

Temperature range |

-30°C / +80°C |

|

Food approval [FDA] |

yes |

|

Pulley Factor |

30 |

Product features: high oil- and fat-resistance

TPU 92

|

Thickness |

2,3 mm |

|

Material / Hardness |

Polyurethan / 92° Shore A |

|

Colour |

white |

|

Surface |

smooth |

|

Temperature range |

-30°C / +80°C |

|

Food approval [FDA] |

no |

|

Pulley Factor |

30 |

Product features: abrasion, oil- and fat-resistance

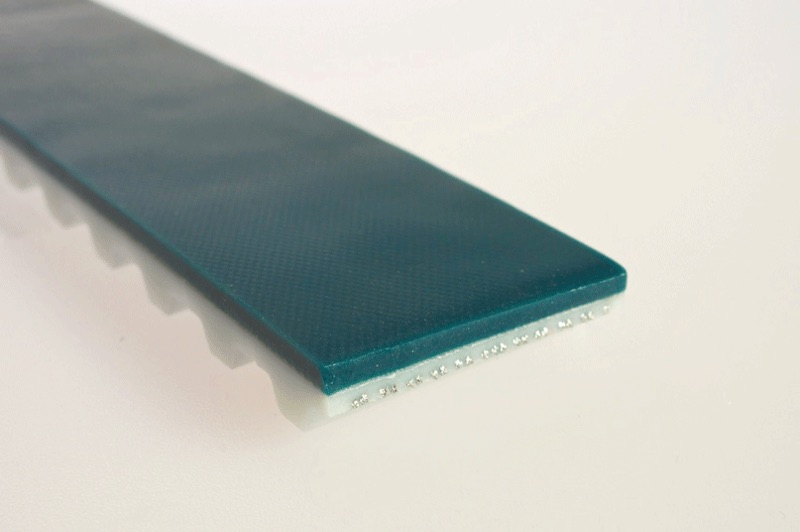

TPU 60 petrol

|

Thickness |

2 / 3 mm |

|

Material / Hardness |

Polyurethan / 92° Shore A |

|

Colour |

petrol |

|

Surface |

smooth |

|

Temperature range |

-30°C / +80°C |

|

Food approval [FDA] |

no |

|

Pulley Factor |

25 |

Product features: abrasion, oil- and fat-resistance

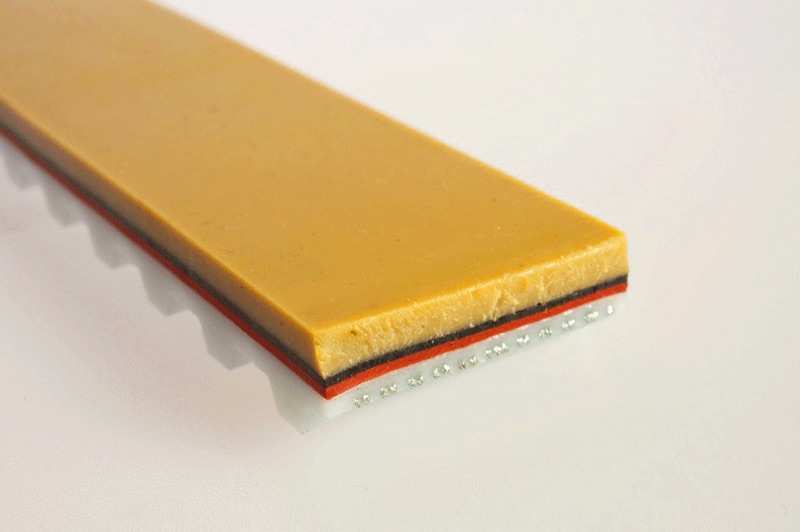

Vulkollan D15

|

Thickness |

1 / 3 mm |

|

Material / Hardness |

Vulkollan / 77-87° Shore A |

|

Colour |

tan |

|

Surface |

smooth |

|

Temperature range |

-15°C / +80°C |

|

Food approval [FDA] |

no |

|

Pulley Factor |

30 |

Product features: high oil- and fat-resistance, hydrolysis consistancy

PVC 45 petrol

|

Thickness |

2,2 mm |

|

Material / Hardness |

PVC / 45° Shore A |

|

Colour |

blue |

|

Surface |

smooth |

|

Temperature range |

-10°C / +60°C |

|

Food approval [FDA] |

no |

|

Pulley Factor |

20 |

Product features: abrasion, oil- and fat-resistance, acid- and base-resistance

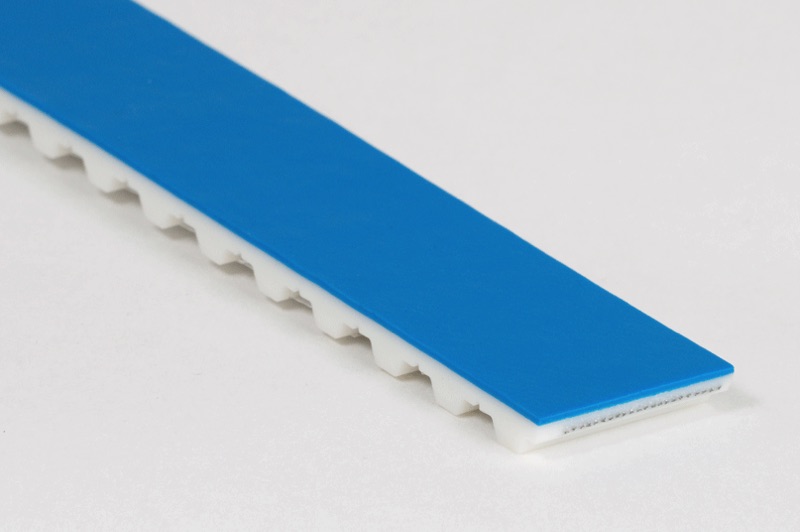

PVC 60 sky-blue F

|

Thickness |

2 mm |

|

Material / Hardness |

PVC / 60° Shore A |

|

Colour |

sky-blue |

|

Surface |

smooth |

|

Temperature range |

-10°C / +80°C |

|

Food approval [FDA] |

yes |

|

Pulley Factor |

20 |

Product features: high oil- and fat-resistance

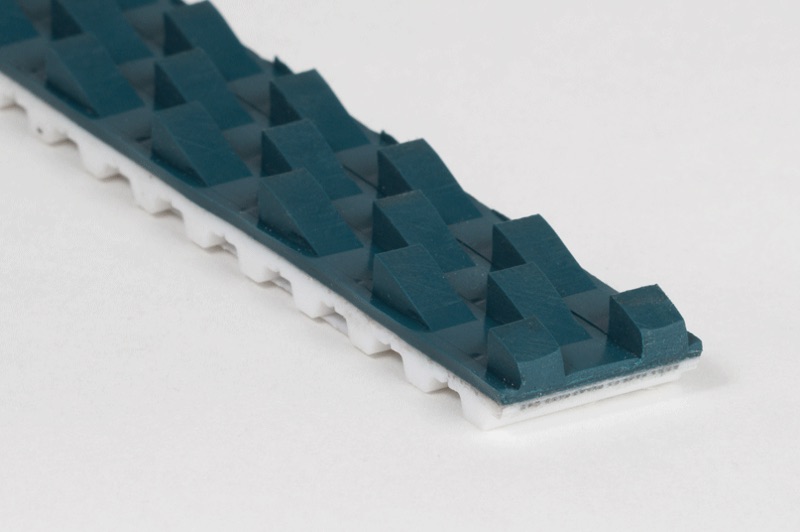

PVC 65 Haifish

|

Thickness |

7 mm |

|

Material / Hardness |

PVC / 65° Shore A |

|

Colour |

petrol |

|

Surface |

grip structure |

|

Temperature range |

-20°C / +70°C |

|

Food approval [FDA] |

no |

|

Pulley Factor |

25 |

Product features: adhesive, easy release property

PVC S12

|

Thickness |

1,2 mm |

|

Material / Hardness |

PVC / 60° Shore A |

|

Colour |

white |

|

Surface |

diagonal groove |

|

Temperature range |

-10°C / +70°C |

|

Food approval [FDA] |

no |

|

Pulley Factor |

25 |

Product features: adhesive, limited oil- and fat-resistance

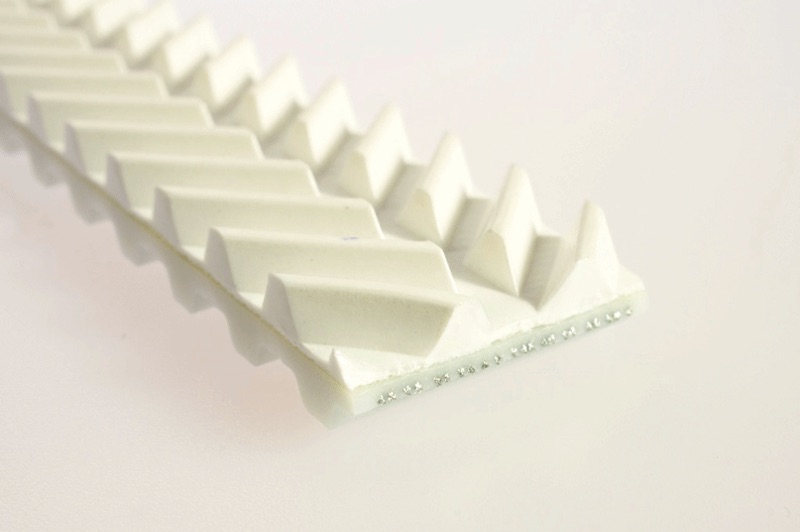

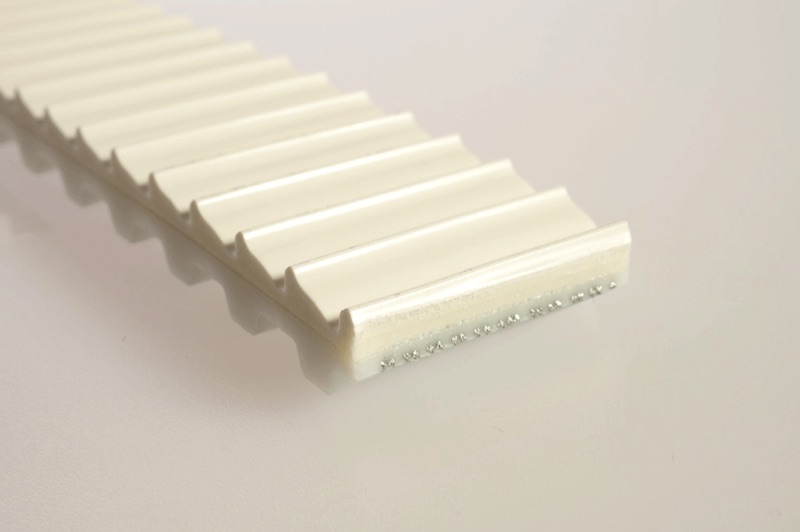

PVC S27

|

Thickness |

4,5 mm |

|

Material / Hardness |

PVC / 60° Shore A |

|

Colour |

white |

|

Surface |

herringbone structure |

|

Temperature range |

-10°C / +70°C |

|

Food approval [FDA] |

no |

|

Pulley Factor |

25 |

Product features: adhesive, good water expiry by herringbone structure

PVC 60 white F

|

Thickness |

2 mm |

|

Material / Hardness |

PVC / 60° Shore A |

|

Colour |

white |

|

Surface |

smooth |

|

Temperature range |

-10°C / +80°C |

|

Food approval [FDA] |

yes |

|

Pulley Factor |

20 |

Product features: adhesive, oil- and fat-resistance

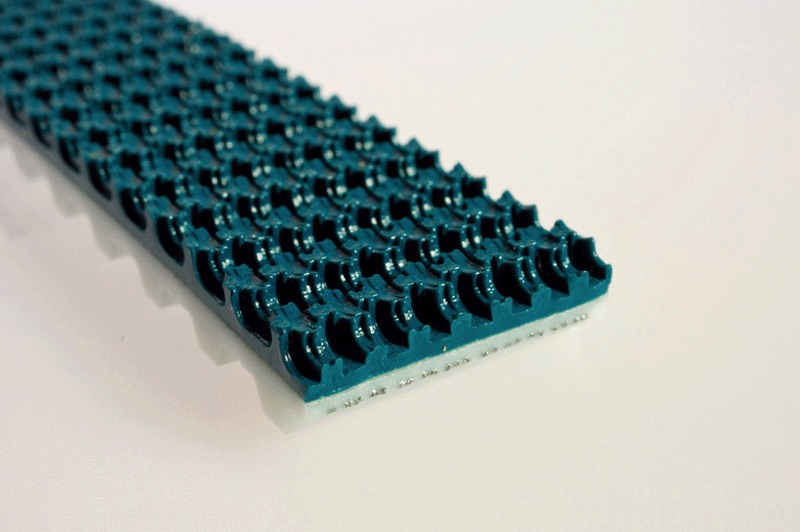

PVC S6

|

Thickness |

3 mm |

|

Material / Hardness |

PVC / 40° Shore A |

|

Colour |

petrol |

|

Surface |

grip structure |

|

Temperature range |

-25°C / +70°C |

|

Food approval [FDA] |

no |

|

Pulley Factor |

25 |

Product features: adhesive, limited oil- and fat-resistance

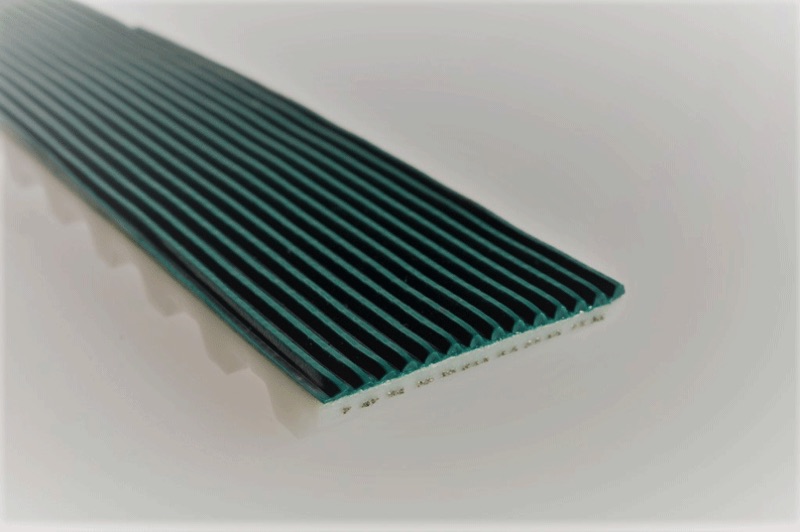

PVC S7

|

Thickness |

1,2 mm |

|

Material / Hardness |

PVC / 60° Shore A |

|

Colour |

petrol |

|

Surface |

longitudinal groove |

|

Temperature range |

-10°C / +70°C |

|

Food approval [FDA] |

no |

|

Pulley Factor |

25 |

Product features: adhesive, oil- and fat-resistance

PVC S13

|

Thickness |

3 mm |

|

Material / Hardness |

PVC / 60° Shore A |

|

Colour |

white |

|

Surface |

saw tooth |

|

Temperature range |

-10°C / +70°C |

|

Food approval [FDA] |

no |

|

Pulley Factor |

25 |

Product features: adhesive, limited oil- and fat-resistance

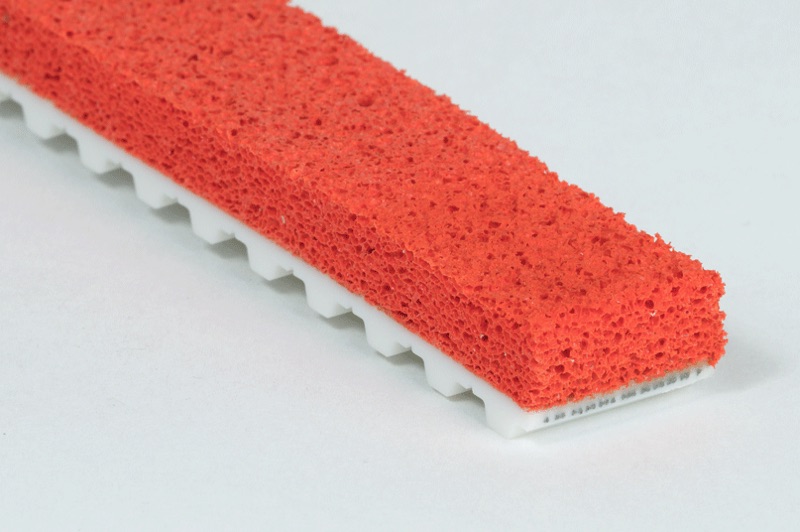

Linatex HM

|

Thickness |

2 / 3 / 4 / 5 / 6 / 7 / 8 / 10 mm |

|

Material / Hardness |

Nature rubber / 40° Shore A |

|

Colour |

red |

|

Surface |

smooth |

|

Temperature range |

-40°C / +70°C |

|

Food approval [FDA] |

no |

|

Pulley Factor |

15 |

Product features: highly adhesive, high wear resistance, cut resistance

Linaplus F

|

Thickness |

3 / 5 / 6 mm |

|

Material / Hardness |

Natural Rubber / 40° Shore A |

| Colour | white |

|

Surface |

smooth |

|

Temperature range |

-40°C / +70°C |

|

Food approval [FDA] |

yes |

|

Pulley Factor |

15 |

Product features: highly adhesive, superior rebound resilience, excellently resistant to wet abrasion, high coefficient of friction surface

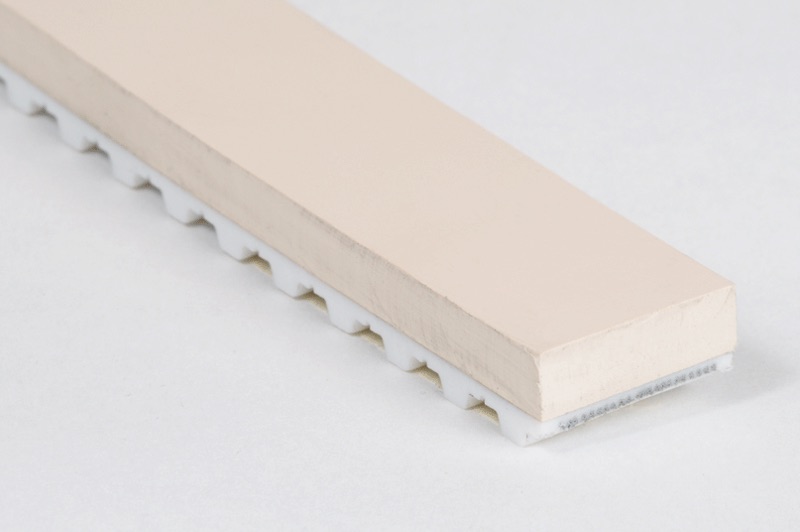

Correx

|

Thickness |

4 / 6 / 8 / 10 mm |

|

Material / Hardness |

Natural Rubber / 36° Shore A |

| Colour | beige |

|

Surface |

smooth |

|

Temperature range |

-15°C / +70°C |

|

Food approval [FDA] |

no |

|

Pulley Factor |

20 |

Product features: abrasion-resistance, adhesive, high coefficient of friction, resistance to wet abrasion

SBR 67

|

Thickness |

3 / 4 / 6 mm |

|

Material / Hardness |

SBR / 65° Shore A |

| Colour | light |

|

Surface |

smooth |

|

Temperature range |

-30°C / +70°C |

|

Food approval [FDA] |

limited extent |

|

Pulley Factor |

20 |

Product features: acid- and alkali-resistance

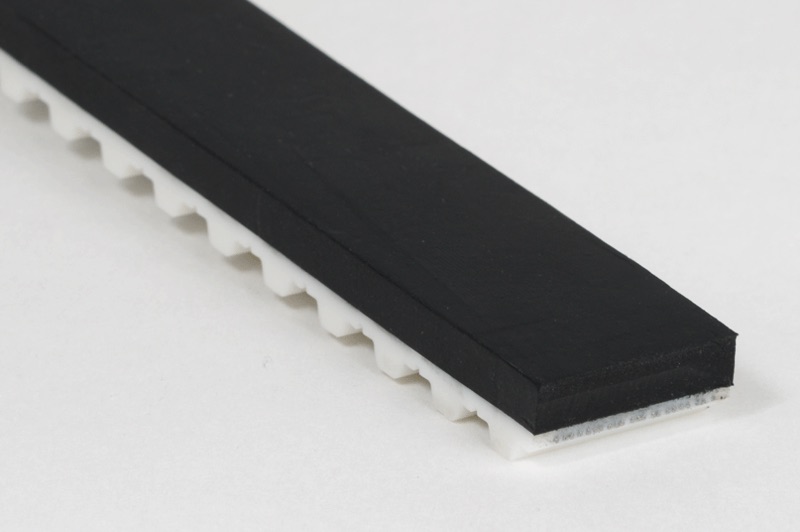

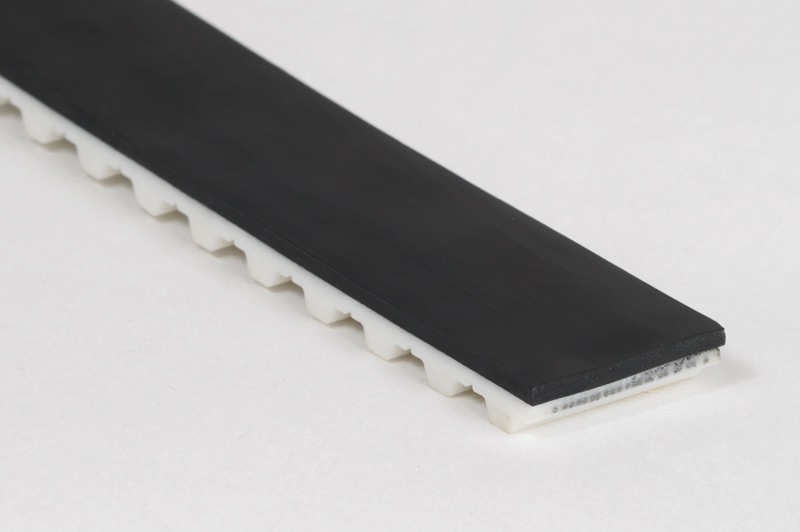

EPDM Black

|

Thickness |

6 / 10 mm |

|

Material / Hardness |

EPDM / 70° Shore A |

| Colour | black |

|

Surface |

smooth |

|

Temperature range |

-40°C / +100°C |

|

Food approval [FDA] |

no |

|

Pulley Factor |

35 |

Product features: high weatherability and ozone resistance, high water resistance

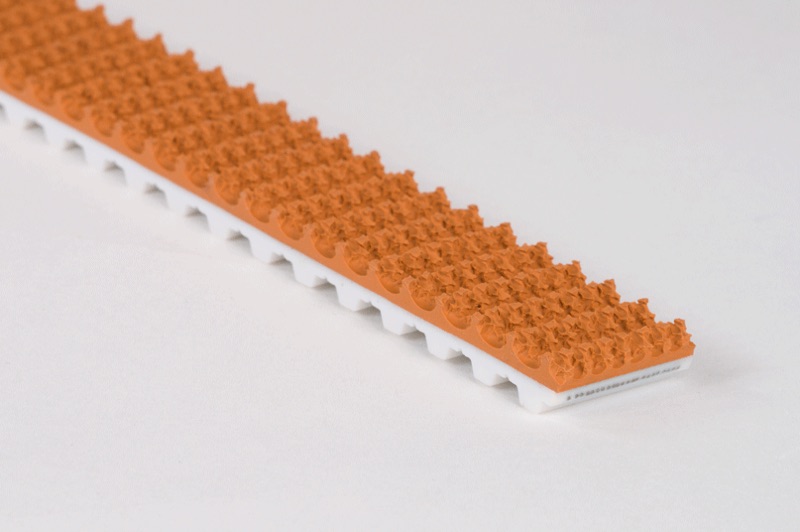

S37-40 brown

|

Thickness |

4,3 mm |

|

Material / Hardness |

Synthetic rubber / 40° Shore A |

| Colour | brown |

|

Surface |

grip structure |

|

Temperature range |

-20°C / +80°C |

|

Food approval [FDA] |

no |

|

Pulley Factor |

20 |

Product features: adhesive, constant coefficient of friction

Linatrile

|

Thickness |

3 / 6 mm |

|

Material / Hardness |

Nitrile / 55° Shore A |

| Colour | orange |

|

Surface |

smooth |

|

Temperature range |

-20°C / +110°C |

|

Food approval [FDA] |

no |

|

Pulley Factor |

20 |

Product features: highly adhesive, constant coefficient of friction, high temperature consistency, oil- and fat-resistance

Linard 60

|

Thickness |

3 / 6 mm |

|

Material / Hardness |

Natural rubber / 60° Shore A |

| Colour | red |

|

Surface |

smooth |

|

Temperature range |

-40°C / +75°C |

|

Food approval [FDA] |

no |

|

Pulley Factor |

20 |

Product features: superior rebound resilience, highly elastic, excellent gasket features

RP430

|

Thickness |

2 / 3 / 4 / 5 mm |

|

Material / Hardness |

Natural rubber / 39° Shore A |

| Colour | yellow |

|

Surface |

smooth |

|

Temperature range |

-30°C / +70°C |

|

Food approval [FDA] |

no |

|

Pulley Factor |

20 |

Product features: abrasion-resistance, acid- and alkali-resistance, oil- and fat-resistance

Viton Black

|

Thickness |

2 / 3 mm |

|

Material / Hardness |

Fluorocarbon rubber / 75° Shore A |

| Colour | black |

|

Surface |

smooth |

|

Temperature range |

-20°C / +250°C (short acting +275°C) |

|

Food approval [FDA] |

no |

|

Pulley Factor |

40 |

Product features: high chemical-, acid-, alkali and oil-resistance, high heat stability

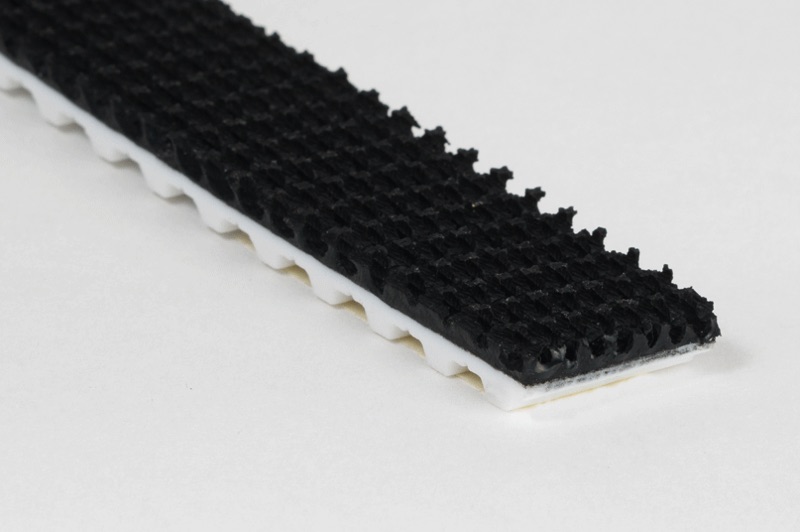

S37-60 Black

|

Thickness |

3,5 mm |

|

Material / Hardness |

Natural rubber / 60° Shore A |

| Colour | black |

|

Surface |

grip structure |

|

Temperature range |

-20°C / +70°C |

|

Food approval [FDA] |

no |

|

Pulley Factor |

25 |

Product features: adhesive, constant coefficient of friction

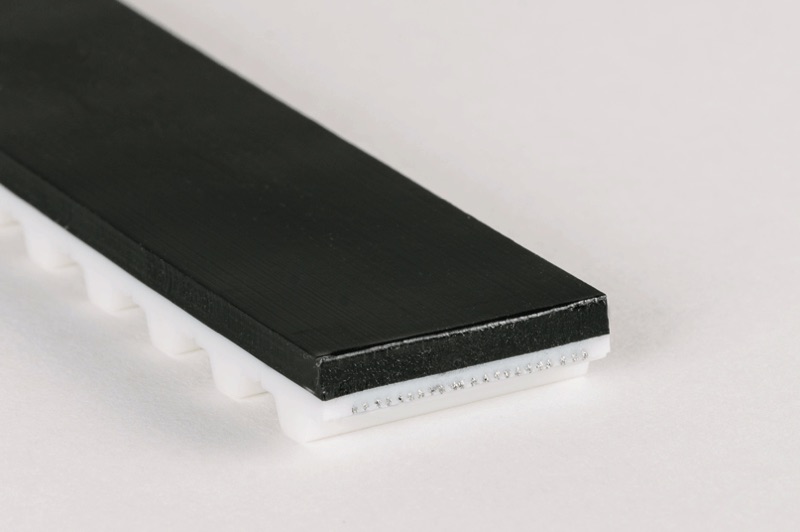

Nitrile

|

Thickness |

2 / 3 / 4 mm |

|

Material / Hardness |

Nitrile / 60-70° Shore A |

| Colour | black |

|

Surface |

smooth |

|

Temperature range |

-20°C / +110°C |

|

Food approval [FDA] |

no |

|

Pulley Factor |

30 |

Product features: adhesive, limited oil- and fat-resistance

Celloflex

|

Thickness |

1 / 2 / 3 / 4 / 5 / 6 / 8 / 10 mm |

|

Material / Hardness |

Closed-cell polyurethane foam / 350 kg/m³ |

| Colour | beige |

|

Surface |

smooth |

|

Temperature range |

-30°C / +80°C |

|

Food approval [FDA] |

no |

|

Pulley Factor |

16 |

Product features: limited oil- and fat-resistance, good flexibility and damping characteristics

PU Yellow

|

Thickness |

2 / 3 / 4 / 5 / 6 / 7 / 8 / 10 mm |

|

Material / Hardness |

Polyurethan / 850 kg/m³ |

| Colour | yellow |

|

Surface |

smooth |

|

Temperature range |

-10°C / +80°C |

|

Food approval [FDA] |

no |

|

Pulley Factor |

20 |

Product features: adhesive, abrasion, oil- and fat-resistance

Sylomer yellow

|

Thickness |

5 / 10 / 15 mm |

|

Material / Hardness |

Polyurethan / 160 kg/m³ |

| Colour | yellow |

|

Surface |

smooth |

|

Temperature range |

-30°C / +70°C |

|

Food approval [FDA] |

no |

|

Pulley Factor |

10 |

Product features: good flexibility and compressible, adhesive, oil- and fat-resistance

Sylomer green

|

Thickness |

3 / 5 / 6 / 10 / 15 / 18 / 22 mm |

|

Material / Hardness |

Polyurethan / 280 kg/m³ |

| Colour | green |

|

Surface |

smooth |

|

Temperature range |

-30°C / +70°C |

|

Food approval [FDA] |

no |

|

Pulley Factor |

14 |

Product features: good flexibility and compressible, adhesive, oil- and fat-resistance

Sylomer red

|

Thickness |

8 / 10 / 18 mm |

|

Material / Hardness |

Polyurethan / 510 kg/m³ |

| Colour | red |

|

Surface |

smooth |

|

Temperature range |

-30°C / +70°C |

|

Food approval [FDA] |

no |

|

Pulley Factor |

17 |

Product features: flexibility and compressible, adhesive, oil- and fat-resistance

Porol

|

Thickness |

3 / 5 / 6 / 8 / 10 / 15 mm |

|

Material / Hardness |

EPDM-S / 175 kg/m³ |

| Colour | black |

|

Surface |

smooth |

|

Temperature range |

-50°C / +110°C |

|

Food approval [FDA] |

no |

|

Pulley Factor |

10 |

Product features: limited oil- and fat-resistance, antistatic and abrasion-resistant

Spong Rubber

|

Thickness |

10 mm |

|

Material / Hardness |

Rubber / 270 kg/m³ |

| Colour | orange |

|

Surface |

open cell |

|

Temperature range |

-10°C / +80°C |

|

Food approval [FDA] |

no |

|

Pulley Factor |

10 |

Product features: very smooth and compressible, abrasion resistance

Sylomer blue

|

Thickness |

3 / 5 / 6 / 10 / 15 mm |

|

Material / Hardness |

Polyurethan / 220 kg/m³ |

| Colour | blue |

|

Surface |

smooth |

|

Temperature range |

-30°C / +70°C |

|

Food approval [FDA] |

no |

|

Pulley Factor |

12 |

Product features: good flexibility and compressible, adhesive, oil- and fat-resistance

Sylomer brown

|

Thickness |

8 / 10 / 18 mm |

|

Material / Hardness |

Polyurethan / 380 kg/m³ |

| Colour | brown |

|

Surface |

smooth |

|

Temperature range |

-30°C / +70°C |

|

Food approval [FDA] |

no |

|

Pulley Factor |

15 |

Product features: good flexibility and compressible, adhesive, oil- and fat-resistance

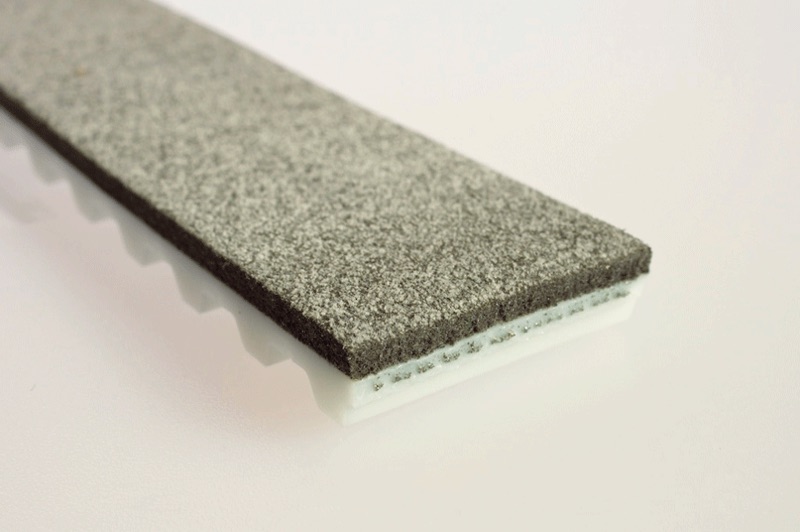

NF 25

|

Thickness |

2,5 mm |

|

Material / Hardness |

Needle felt |

| Colour | anthracite |

|

Surface |

needle felt |

|

Temperature range |

-10°C / +120°C |

|

Food approval [FDA] |

no |

|

Pulley Factor |

30 |

Product features: abrasion-resistant, dimensionally stable

Kevlar PBO

|

Thickness |

4-2 / 6-2 / 8-2 mm |

|

Material / Hardness |

Zylon |

| Colour | brown |

|

Surface |

needle felt |

|

Temperature range |

-10°C / +400°C |

|

Food approval [FDA] |

no |

|

Pulley Factor |

on request |

Product features: short-time temperature resistance 500°C, maximum contact for 10 minutes

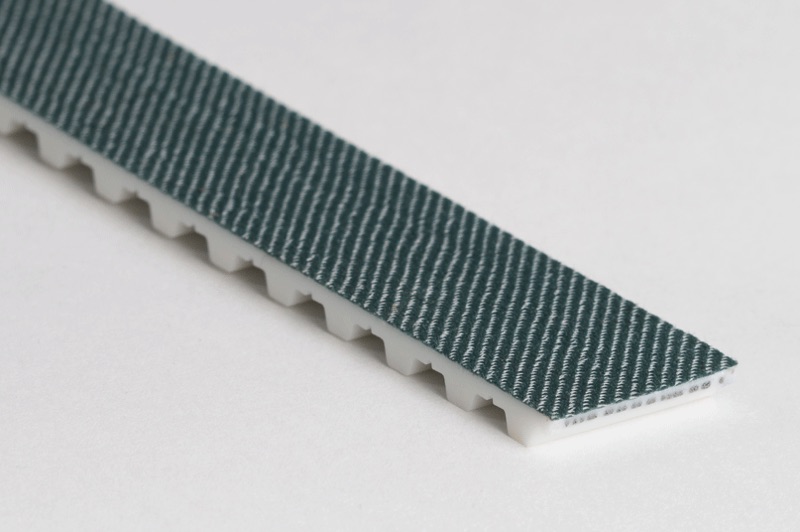

PA green

|

Thickness |

0,4 mm |

|

Material / Hardness |

Polyamid |

| Colour | green |

|

Surface |

textile structure |

|

Temperature range |

-30°C / +80°C |

|

Food approval [FDA] |

no |

|

Pulley Factor |

– |

Product features: high abrasion-resistance, non-adhesive

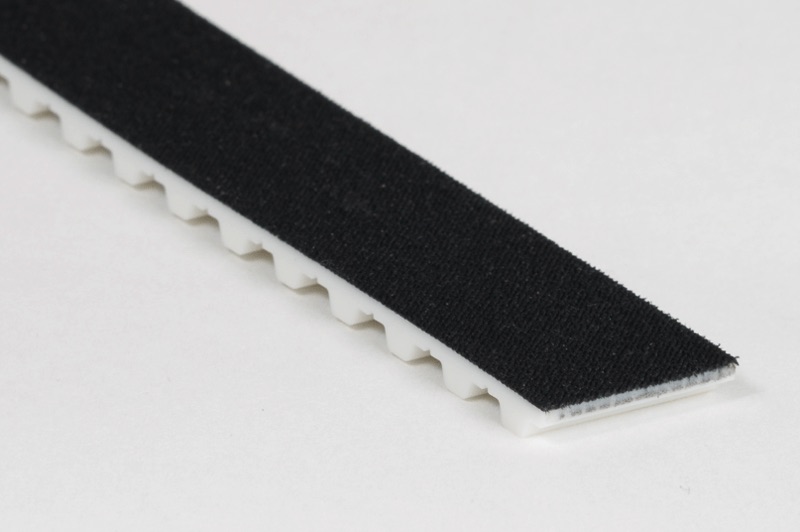

PA black

|

Thickness |

0,4 mm |

|

Material / Hardness |

Polyamid |

| Colour | black |

|

Surface |

textile structure |

|

Temperature range |

-30°C / +80°C |

|

Food approval [FDA] |

no |

|

Pulley Factor |

– |

roduct features: antistatic, high abrasion resistance, non-adhesive

Kevlar

|

Thickness |

6 / 8 / 10 mm |

|

Material / Hardness |

Kevlar |

| Colour | yellow |

|

Surface |

needle felt |

|

Temperature range |

-10°C / +250°C |

|

Food approval [FDA] |

no |

|

Pulley Factor |

on request |

Product features: short-time temperature resistance 500°C, maximum contact for 10 minutes

Chrome leather

|

Thickness |

ca. 2 mm |

|

Material / Hardness |

Leather |

| Colour | light gray |

|

Surface |

leather structure |

|

Temperature range |

-0°C / +60°C |

|

Food approval [FDA] |

no |

|

Pulley Factor |

30 |

Product features: abrasion-resistant, oil- and fat-resistance, constant grip and release property

PA gray

|

Thickness |

0,4 mm |

|

Material / Hardness |

Polyamid |

| Colour | gray |

|

Surface |

textile structure |

|

Temperature range |

-30°C / +80°C |

|

Food approval [FDA] |

no |

|

Pulley Factor |

– |

Product features: high abrasion-resistance, non-adhesive

PA white

|

Thickness |

0,4 mm |

|

Material / Hardness |

Polyamid |

| Colour | white |

|

Surface |

textile structure |

|

Temperature range |

-30°C / +80°C |

|

Food approval [FDA] |

no |

|

Pulley Factor |

– |

Product features: high abrasion-resistance, non-adhesive