INO Process & Conveyor Belts Endless Joint Types

Endless Joint TypesThe INO Process & Conveyor Belts are either welded or mechanically joined into endless belts.

Our joining methods are described here:

I. Welded joints

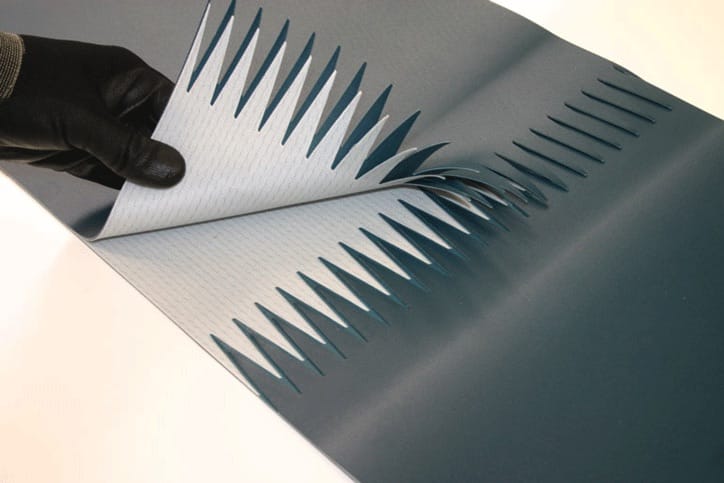

01 Finger joint

In this method, fingers are punched into the ends to be joined, and then tacked together and welded under pressure and heat. This method is especially suitable for single-layered belts.

Details

| Length of the joint | 70 mm |

| Length of the fingers | 70 mm |

| Width of the fingers | 15 mm |

| Belt types | INFAB, INPUR, INV, INVOR, INFIN, INHYT, INSIL |

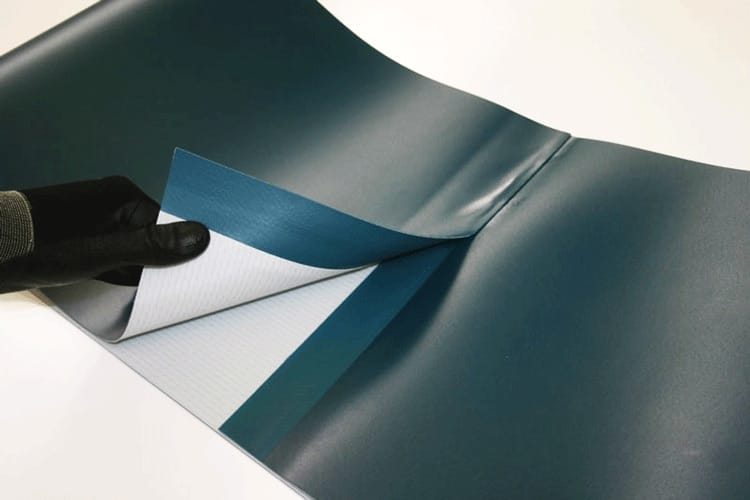

02 Overlapped finger joint

We recommend the overlapped finger joint. Again, in this case, the ends to be joined are split into layers. Next, fingers are punched into the ends, which are then tacked together and welded under pressure and heat into an endless belt.

Details

| Length of the joint | 100 (2×50) mm |

| Length of the fingers | 50 mm |

| Width of the fingers | 15 mm |

| Belt types | INFAB, INPUR, INV, INVOR, INFIN, INHYT, INSIL (mind. 2 Lagen) |

03 Layered joint

In a layered joint, the ends to be joined are split into layers and equally overlapped – although at an angle of 80° in order to ensure reliable running around the pulley.

Details

| Angle | 80° |

| Length of the joint (2-plies) | 40 mm |

| Length of the joint (3-plies) | 80 mm |

| Belt types | INFAB, INPUR, INV, INVOR, INFIN, INHYT, INSIL (mind. 2 Lagen) |

04 Skived joint

We use the skived joint for our rubber and felt belts. In this case, the ends to be joined are split at an 80° oblique angle, overlapped to equal amounts and bonded into an endless belt using adhesive and pressure.

Details

| Angle | 80° |

| Length of the joint | 80 mm |

| Belt types | INFELT, INRUB |

Limitations: Only thermoplastic belts can be welded. Otherwise, belts are glued. Minimum belt length: 800 mm, maximum belt width: 3,000 mm

II. Plastic spiral joint

The plastic spiral joint is excellently suited to fine applications. It can be used for all types of belt.

III. Mechanical joints

For applications that do not allow either installation of an endless belt or welding into the system, INO process and conveyor belts can be equipped with mechanical joints.

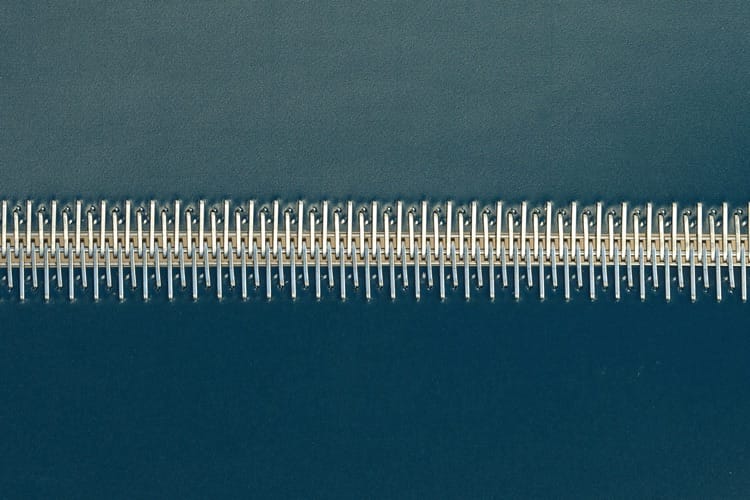

01 Hook in round design

Metal hooks are pressed into the ends of the belt so that the belt can be joined endlessly using a metal rod. In embossed belts, the cover layer is removed so that the hooks do not project beyond the belt surface.

Details

| Type | Belt Thicknesses [mm] | Length of Hook* [mm] | min.Pulley-Ø [mm] |

| A36 SLXSP- SS-600 | -1,5 | 600 | 25 |

| A36 SP- SS-600 | 1,5-2 | 600 | 50 |

| A36- SS-600 | 2-3 | 600 | 50 |

| A40- SS-600 | 3-4 | 600 | 50 |

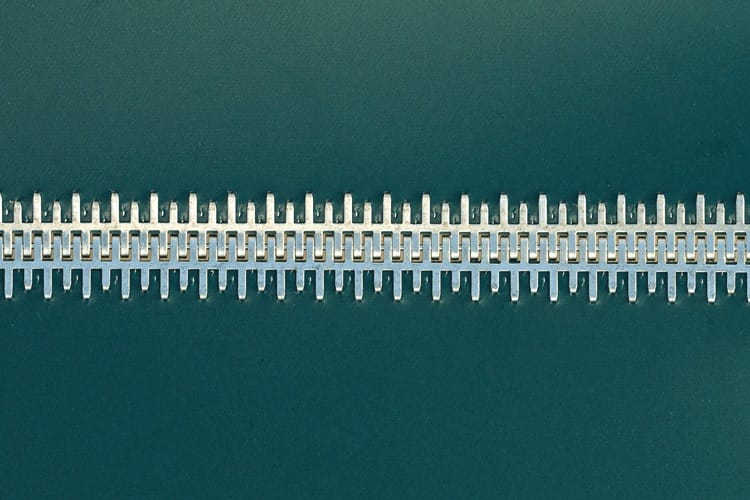

02 hooks in flat design

Metal hooks are pressed into the ends of the belt so that the belt can be joined endlessly using a metal rod. In embossed belts, the cover layer is removed so that the hooks do not project beyond the belt surface.

Details

| Type | Belt Thicknesses [mm] | Length of Hook* [mm] | min.Pulley-Ø [mm] |

| G001A- SS-300 W | -1,5 | 300 | 25 |

| G005A- SS-1200 W | 1,5-2 | 1200 | 40 |

| G005A- SS-1500 W | 2-2,5 | 1200 | 40 |

| G006A- SS-1200 W | 2,5-3,5 | 1200 | 50 |

03 panel connector

Metal hooks are pressed into the ends of the belt so that the belt can be joined endlessly using a metal rod. In embossed belts, the cover layer is removed so that the hooks do not project beyond the belt surface.

Details

| Type | Belt Thicknesses [mm] | Length of Hook* [mm] | min.Pulley-Ø [mm] |

| RS62 Sj24 / 600 NCS | 1,5-3,2 | 600 | 50 |

| RS125 Sj24 / 600 NCS | 3,2-4,8 | 600 | 75 |

* For widths greater than the hook length, the hooks are arranged side-by-side.

Questions?

Downloads

Download all catalogues and brochures here

Sample catalogue

Obtain a sample catalogue or request more information from here